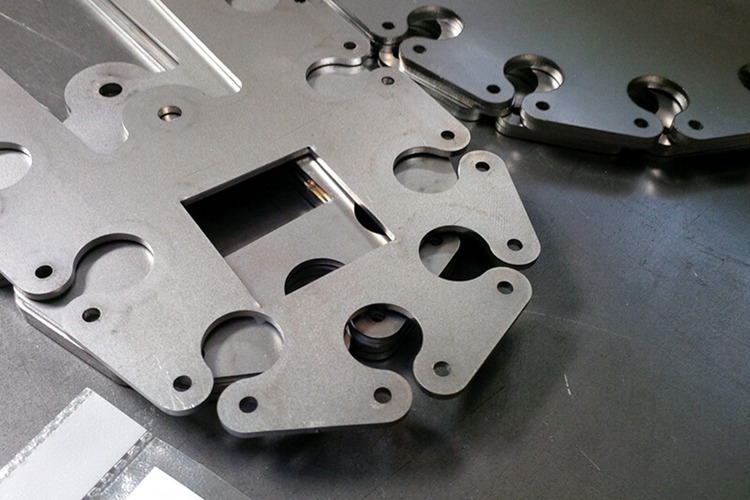

A metal laser cutting machine is a high-tech device that uses a focused laser beam to cut through metal sheets and plates. The laser beam is generated by a powerful fiber laser source, and is directed onto the metal surface through a series of mirrors and lenses. The intense heat of the laser beam melts, vaporizes, or burns away the metal, creating a clean and precise cut.

These machines are capable of cutting a wide variety of metals, including steel, aluminum, copper, brass, and stainless steel. They can handle different thicknesses of metal, ranging from thin sheets to thick plates, depending on the power of the laser and the capabilities of the machine.

Based on the fiber laser power, we provide 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W fiber laser cutting machine and other high power laser cutting machines to realize your metal cutting designs, ideas, and plans.

Metal Laser Cutter Advantages

1. Automatic focusing mode of the laser head reduces human interference with a focusing speed of 10m/min and repeated positioning accuracy of 50um.

2. The blade worktable is arranged in a staggered form, which can hold the metal sheet steadily.

3. Aircraft-grade aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

4. The dust removal system can remove all the smoke generated from the cutting process with large air volume. This helps protect the operator’s health and the working environment.

5. Automatic lubrication method saves more human labor, reduces maintenance time, and greatly improves work efficiency.

Application of Fiber Laser Cutting Machine

The laser metal cutting machine is widely used to cut various metal sheet products in the advertising, craft, decoration, and other industries. It is suitable for cutting carbon steel, stainless steel, aluminum, brass, and copper parts, signs, crafts, logos, letters, etc, and has been widely used in the processing of metal sheet fabrication, steel furniture, fire pipes, automotive, fitness equipment, agricultural and forestry machinery, food machinery, advertising, electrical cabinets, elevators and other industries.

-

Fiber Laser Cutting MachinesFiber laser cutting machines use a fiber laser source, which is known for its high efficiency, reliability, and low maintenance. These machines are suitable for cutting a wide variety of metals, including thin sheets and thick plates. They are also energy-efficient and have a long lifespan.

-

CO₂ Laser Cutting MachinesCO₂ laser cutting machines use a gas laser source, which is capable of cutting thicker metals and materials with higher reflectivity. These machines are often used for applications that require high power and large cutting areas. However, they are less energy-efficient and require more maintenance than fiber laser cutting machines.

-

Hybrid Laser Cutting Machines

Hybrid laser cutting machines combine the benefits of fiber and CO₂ lasers. They can cut a wide variety of metals and thicknesses with high precision and speed. These machines are often used for applications that require both high power and fine detail.